|

|

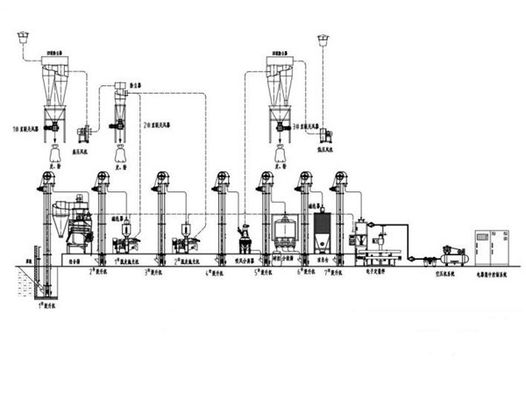

quinoa processing line, quinoa processing machines, quinoa saponin removing machine

|

Product Details:

Payment & Shipping Terms:

|

Detailed Product Description

| Processing: | Remove Quinoa Saponin | Capacity: | 10-12t/day |

|---|---|---|---|

| Peeling Machine: | 2pcs | Grading Machine: | 1pc |

| Shipping: | EXW,FOB,CNF,CIF | Warranty: | One Year |

quinoa processing line, quinoa processing machines, quinoa saponin removing machine

![]()

specification :

| 10-12T/day quinoa processing line | ||||||

| No. | machine | Model | QTY | Power (KW) | Remarks | |

| Unit | Total | |||||

| 一 | Cleaning section | |||||

| 1 | Bucket elevator | TDTG20/9 | 1pc | 0.75 | 0.75 | Barrel cold-rolled plate ≥1.5mm/Q235, head and tail 4mm/Q235 plate production, cover plate 2mm, the periphery adopts occlusal technology, high-strength bucket belt,strong rigidity |

| 2 | Combined destoner | TQLQ-85 | 1pc | 0.16*2 | 0.32 | The motor adopts domestic first-line brand vibration motor, the motor base is cut with 10mm national standard steel plate, the frame is welded with national standard 3mm profile, and the rubber spring is made of imported engineering rubber. |

| 3 | Direct-connected air blower | TGFZ-5L | 1pc | 0.75 | 0.75 | 1. Natural aging treatment, impeller grinder technology 2. Case HT-250 roll carburizing and quenching treatment 3. Good closed air effect, no material leakage |

| 4 | Low pressure fan | 4-72№4A | 1pc | 5.5 | 5.5 | The motor adopts the domestic first-line brand, the frame adopts the national standard 3mm profile welding, the body adopts the national standard 3mm steel plate cutting and welding, the fan impeller is adjusted by dynamic balance, and the vibration reduction device is installed. |

| 5 | Low-pressure wind network |

1 set |

Carbon steel material (thickness t≥1.2mm) spray treatment | |||

| 6 | Quadruple dust collector | φ600 |

1 pc |

0 | Carbon steel material (thickness t≥1.5mm) spray treatment | |

| 7 | Total | 7.32 | ||||

| 二 | milling and finished product collection section | |||||

| 1 | Bucket elevator | TDTG20/9 | 6pcs | 0.75 | 4.5 | Barrel cold-rolled plate ≥1.5mm/Q235, head and tail 4mm/Q235 plate production, cover plate 2mm, the periphery adopts occlusal technology, high-strength bucket belt, bucket, strong rigidity |

| 2 | Peeling polishing machine |

NF-150 |

2pcs | 18.5 | 37 | The frame adopts 6mm national standard Q235 plate laser cutting and welding. The main shaft is made of 45# steel and tempered by heat treatment. The equipment adopts axial double air inlet design and is equipped with a strong exhaust system. The temperature low and the chaff discharge effect is good. The feed inlet is controlled by a gear drive mechanism, and the feeding operation is convenient and accurate. The motor adopts Anhui Wannan motor, equipped with a wind pressure monitoring device, which is convenient for online control of the negative pressure in the machine, and keeps the negative pressure stable in the milling room. The bearings are based on Jiangsu Renben. |

| 3 | Suction separator | TXFL45 | 1pc | The frame adopts 3mm national standard profile welding, and the body is 2mm thick Q235 plate laser cutting and welding | ||

| 4 | Grading screen | MMJP63*3 | 1pc | 1.1 | 1.1 | 1. Compact structure, convenient operation of the machine, stable performance 2. Continuous sieving with three-layer sieve surface to separate broken quinoa and whole quinoa |

| 5 | Cold storage | 1CBM | 1pc | 1.5mm prefabricated carbon steel, lined with stainless steel screen, double-sided paint | ||

| 6 | Magnetic separator | TCXT-15 | 2pcs | 0 | Stainless steel material, remove ferrous materials | |

| 7 | Chakron | φ600 | 1pc | 0 | Down-spin 55 type, carbon steel material (thickness t≥1.0mm) sprayed | |

| 8 | Direct-connected air blower | TGFZ-7L |

1 pc |

0.75 | 0.75 | 1. Natural aging treatment, impeller grinder technology 2. Case HT-250 roll carburizing and quenching treatment 3. Good closed air effect, no material leakage |

| 9 | High pressure fan | 6-30№5A |

1 pc |

7.5 | 7.5 | The motor adopts the domestic first-line brand, the frame adopts the national standard 3mm profile welding, the body adopts the national standard 3mm steel plate cutting and welding, the fan impeller is adjusted by dynamic balance, and the vibration reduction device is installed. |

| 10 | High-pressure wind network |

1 set |

0 | Carbon steel material (thickness t≥1.0mm) spray treatment | ||

| 11 | Direct-connected air blower | TGFZ-5L |

1 pc |

0.75 | 0.75 | 1. Natural aging treatment, impeller grinder technology 2. Case HT-250 roll carburizing and quenching treatment 3. Good closed air effect, no material leakage |

| 12 | Quadruple dust collector | φ600 |

1 pc |

0 | Carbon steel material (thickness t≥1.5mm) spray treatment | |

| 13 | Electronic packing machine | DCS-25 |

1 pc |

0.74 | 0.74 | Automatic electronic quantitative weighing, rated packaging volume 10kg-25kg, graduation value 5g, packaging accuracy X (0.1), packaging speed 300-600 bags per hour, power supply AC220 150W, demand air pressure 0.4-0.8MPa |

| 14 | Air compressor system |

1 set |

3 | 3 | Including refrigeration dryer, gas storage tank, gate valve and other gas pipeline fittings | |

| 15 | Total | 55.34 | ||||

![]()

![]()

Contact Details

Anyang fashun Machinery CO.,LTD

Contact Person: Miss. wang

Tel: 86-13698854655

Fax: 86-372-6826359

Send your inquiry directly to us

More food processing machine

-

Mushroom root cutting machine, mushroom cutter machine

-

Shumai Forming Machine, Siomai Making Machine,Semi Auto Siu Mai Machine

-

Fresh Pepper Grinding Machine, Fresh Chili Paste Making Machine

-

Ginger Washing peeling machine, potato peeling machine, carrot washing machine

-

Quinoa Saponin Peeling Machine, Quinoa Processing Line 15T/DAY

-

Shumai Forming Machine, Shaomai Making Machine, Siomai Making Machine,Steam Dumpling